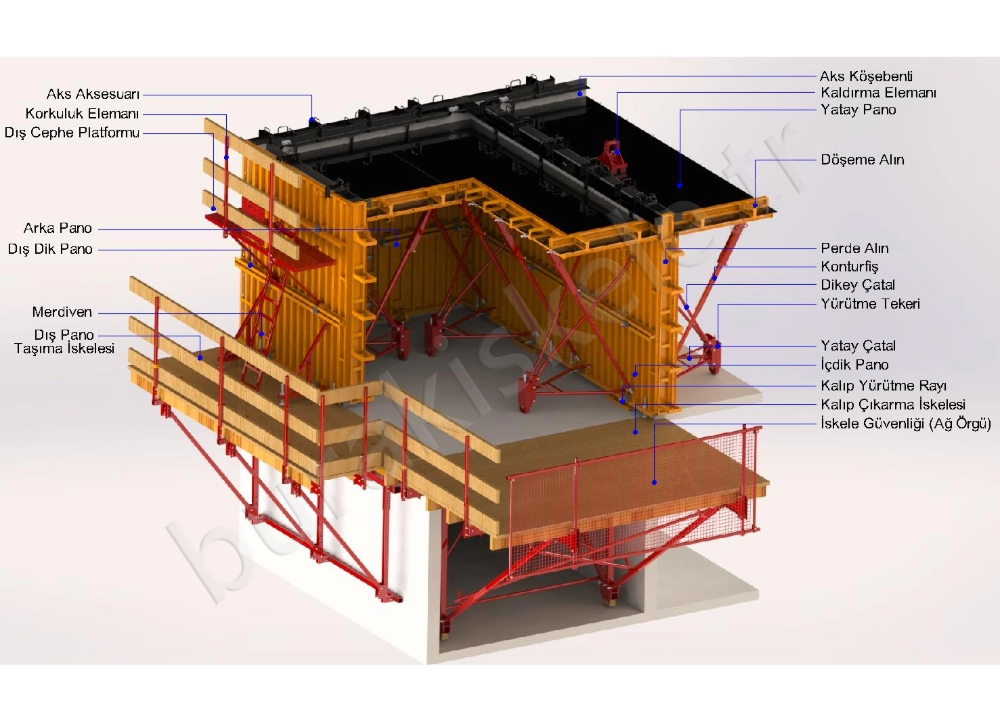

Tunnel Formwork Systems

WHAT IS TUNNEL FORM?

The tunnel form system is a construction method that allows the pouring of shear wall and slab concrete together, making it possible to pour one floor daily or every two days.

ADVANTAGES

Fast pouring time. (e.g., pouring concrete for one floor every 2 days)

When a residential unit is completed and another one is desired, it allows for a new project to be built by manufacturing missing parts, just like a set of Lego pieces.

Unlike conventional forms, it ensures the structure is completed straight without deviations (small or large curvatures in the building).

It provides the possibility of concrete pouring up to 700 times, depending on the usage conditions of one form.

It provides perfect smoothness on concrete surfaces. Decoration applications such as paint and wallpaper can be applied directly to the surface. It does not require extra plastering labor.

(If freezing occurs, using an additive in the concrete) Daily pouring of a formwork with an approximate floor area of $350 \, \text{m}^2$ can be achieved with a team of 15 formworkers, 13 ironworkers, and 2 plumbers.

ECONOMY

It is advantageous compared to industrial ($H20$ timber) and conventional forms.

It provides a $45\%$ cost advantage in projects over 100 residential units compared to other formwork methods.

It makes the reduced construction time economical.

Brick labor is reduced, no plastering is done, and no wooden forms or nails are used.

It reduces iron labor by $20\%$ due to the use of steel mesh.

It reduces the project completion time. For example, when using half-floor formwork in a building,

the shell construction of a 15-story building is completed in 30 days.

SAFETY

Workers on the construction site do not have to lift heavy materials. All materials are transported with the help of a tower crane.

No collapse has been reported in buildings constructed using tunnel forms. Only small cracks have been observed. The structure has always remained standing.

The lifespan of buildings constructed with the tunnel form system is approximately 100 years, depending on the quality of materials used, the concrete class, and the application procedures.

WHY TUNNEL FORM AND EXAMPLES

It is chosen for being economical, sound (healthy), having maximum occupational safety, durability, and most importantly, its ability to remain standing in severe earthquakes without harming anyone's life.

The Erzincan earthquake on March 13, 1992, was measured as magnitude $6.8 \, \text{Mw}$, and 8057 buildings were damaged or destroyed. Only structures built with Tunnel Form passed a successful test.

The Gölcük-Marmara earthquake on August 17, 1999,

was measured as magnitude $7.6 \, \text{Mw}$, and 285,211 homes and 42,902 workplaces were damaged or destroyed. Only structures built with Tunnel Form passed a successful test.

The Van earthquake on October 23, 2011, was measured as magnitude $7.2 \, \text{Mw}$, and 5,739 buildings were seen to be damaged and uninhabitable. Only structures built with Tunnel Form passed a successful test.

The Southeastern-Kahramanmaraş earthquakes on February 6, 2023, were measured as magnitude $7.8 \, \text{Mw}$. This earthquake affected 11 provinces and caused great destruction. 518,000 residences and workplaces were destroyed. 5 million people migrated to different regions. Only structures built with Tunnel Form passed a successful test.

Based on the examples, structures built with Tunnel Form have always maintained their soundness and safety, including in small-scale earthquakes.

'Strong Projects Rise with Solid Foundations.'

Let Us Call You

Yaytaş Mah. Organiza San. 1. Cad. No:17 Yenişehir / Diyarbakır

0(540) 067 0006

0(412) 345 0150

burakiskele.tr

Burak Scaffolding and Formwork

Strong Projects Rise with Solid Foundations.

All rights reserved. The content cannot be copied or used without permission. ( ❗ )

Our cookie policy: no user private data is recorded.

( ❗ )

© 2025 Burak Scaffolding and Formwork